Knick Elektronische Messgeräte GmbH & Co. KG is a German manufacturer of electronic measuring and control devices, represented in Lithuania by UAB Axioma servisas. Founded more than 75 years ago, the company develops and manufactures top quality products for process analysis in the pharmaceutical and biotechnology, chemical, water, food and beverage and energy industries.

Solutions for the most accurate process analysis

Since 1945, we have been manufacturing the highest quality measuring instruments for the analysis of a wide range of industrial and manufacturing processes. Compact, portable, intelligent and automated solutions for the accurate measurement of process fluid parameters such as:

- Acidity (pH)

- Oxidation-reduction potential (ORP)

- Conductivity (COND)

- Dissolved oxygen (O2)

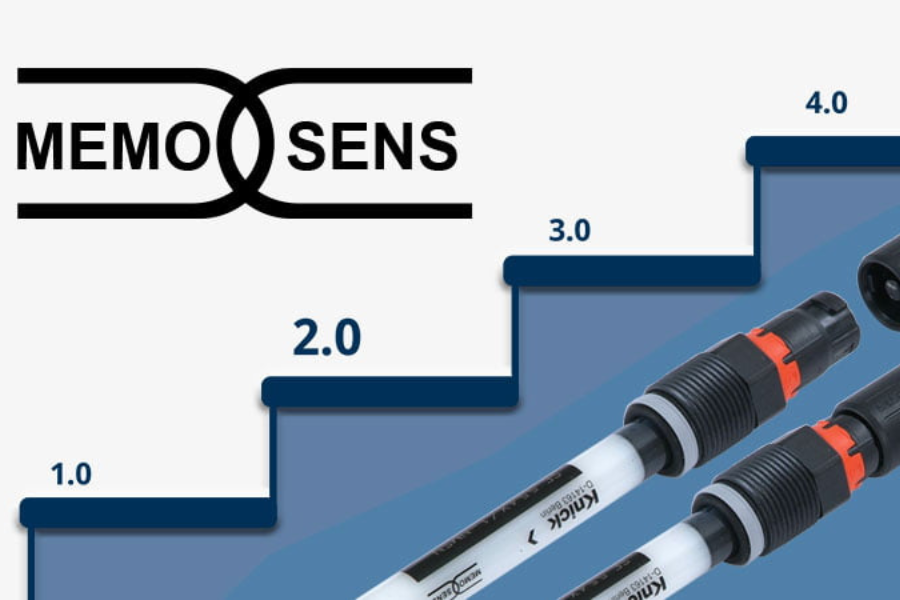

KNICK not only offers tools to determine these parameters, but also develops process analysis solutions. One of their sensors has been considered for many years as the most accurate tool for measuring fluid parameters and modern analysis is unthinkable without the unique Memosens technology.

“Memosens“ for even more reliable measurement

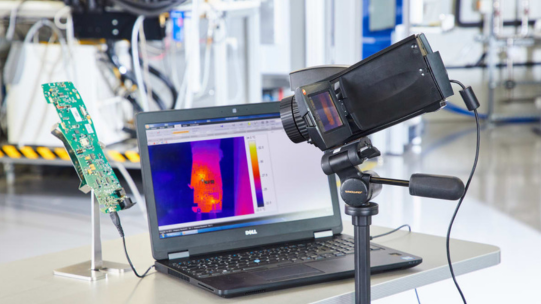

In industrial environments with high humidity or high temperatures, measurements are often inaccurate and, in some cases, even the sensor used can be damaged. An innovative digital sensor with special Memosens technology has been developed in close cooperation with industry, sales partners and equipment suppliers.

This technology allows the sensor to be pre-calibrated by storing the calibration data on the sensor chip and automatically calibrating the sensor when it is installed in the object. This allows faster and more accurate fluid diagnostics in all environments.

Automated systems with no analogues on the market

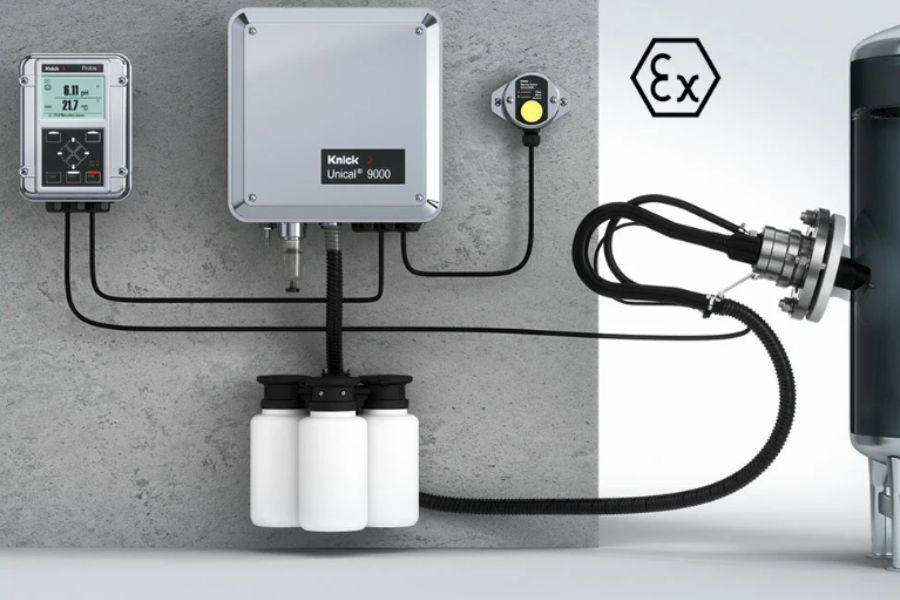

Another exclusive KNICK product is the automatic cleaning (Uniclean 900) and calibration and cleaning (Unical 9000) systems. These systems are unrivalled on the market and reliably measure acidity (pH) parameters and adjust the dosage of other components used in the process to the product based on the readings.

The automatic cleaning or cleaning and calibration system, consisting of a Protos controller, a Memosens digital sensor, a Ceramat or SensoGate pneumatic fitting and a controller, ensures ideal functionality and enables extremely precise measurements. The entire automatic cleaning or cleaning and calibration process is carried out even under difficult process conditions such as high pressure, high temperature or high impurity levels and does not require any additional personnel intervention.

Other products for simpler analysis

KNICK also offers two- or four-channel controllers as well as brackets and fittings that make process analysis even easier. New this year is the Stratos Multi multiparametric controller, which can measure parameters such as pH, ORP, electrical conductivity or dissolved oxygen in water. This controller can measure different or identical parameters but at different points in the process.

The holders and fittings are tailored to meet even the most demanding customer requirements – they can be submerged, installed or used under high pressure. Pneumatic fittings for process analysis are the customer’s preferred choice.

Since 2013, Axioma servisas has been the official representative of these KNICK products in the Baltic States.

Do you have any questions about the manufacturer’s measurement and control instruments? Contact our team by phone +370 652 68982 or orders@axs.eu.